To build a portable weather station for field operations, start by selecting accurate, easy-to-calibrate sensors like anemometers and humidity sensors. Use a microcontroller that supports necessary communication protocols, and plan your circuit carefully to guarantee durability and easy troubleshooting. Focus on designing a lightweight, weatherproof enclosure, and incorporate power management techniques like solar charging. Finally, set up reliable data logging and wireless transmission systems. Keep exploring further steps to assure your station performs well in rugged environments.

Key Takeaways

- Select and calibrate accurate, easy-to-support sensors for environmental parameters like temperature, humidity, and wind speed.

- Design a robust, weatherproof enclosure with proper sensor placement to ensure durability and data accuracy in the field.

- Optimize power management using low-power microcontrollers, solar charging, and sleep modes for extended portable operation.

- Implement reliable wireless data transmission and onboard storage solutions for real-time monitoring and offline access.

- Conduct regular maintenance and calibration checks to ensure sensor precision and system reliability in field conditions.

Selecting the Right Sensors for Your Weather Station

Choosing the right sensors is crucial to guarantee your portable weather station provides accurate and reliable data. Accurate sensors ensure precise measurements, which is essential for effective data visualization and analysis. When selecting sensors, prioritize those that are easy to calibrate, as proper sensor calibration minimizes errors and maintains data integrity over time. Think about the specific environmental conditions you’ll encounter in the field; for example, choose sensors that perform well in high humidity or extreme temperatures. Reliable sensors also simplify data visualization, allowing you to interpret trends quickly. Investing in quality sensors upfront saves you time and effort later, giving you confidence that your weather station delivers trustworthy data for decision-making and field operations. Additionally, selecting sensors with long-term durability can reduce maintenance and replacement costs, ensuring consistent performance in demanding environments.

Choosing a Suitable Microcontroller or Processing Unit

When selecting a microcontroller or processing unit, you’ll need to consider power efficiency to maximize battery life in the field. Make sure it’s compatible with your sensors and offers enough processing power and connectivity options for your data needs. Balancing these factors helps ensure your weather station performs reliably and efficiently. Incorporating space-saving solutions can also help optimize the overall design for portability and ease of deployment.

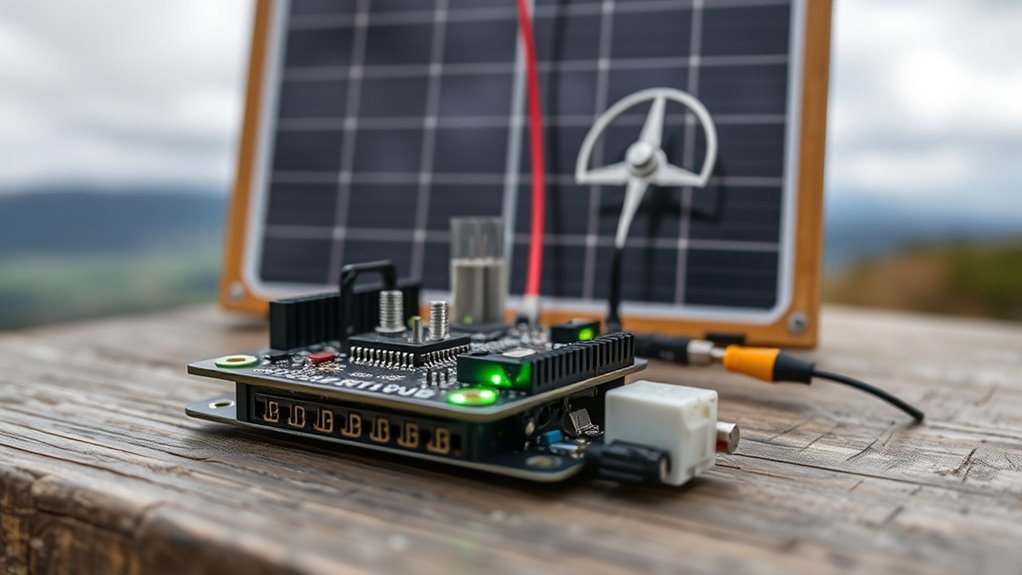

Power Efficiency and Battery Life

Since battery life is critical for field operations, selecting a microcontroller with low power consumption can substantially extend your station’s operational time. Look for options that support sleep modes and efficient power management features. Integrating a solar panel can help recharge the battery, reducing the need for frequent replacements and enhancing endurance. To maximize runtime, focus on battery capacity optimization by choosing the right size and chemistry for your energy demands. Efficient power regulation circuits also prevent unnecessary drain. Keep in mind that a microcontroller with a low overall power profile, combined with solar panel integration, ensures your weather station remains operational longer in remote settings. This balance between hardware choice and renewable energy sources is key to achieving reliable, sustained field performance. Additionally, selecting a best microcontroller with proven low power features can further improve energy efficiency and prolong operational periods.

Compatibility With Sensors

Selecting a microcontroller or processing unit that is compatible with your sensors is essential for seamless data collection and reliable operation. You need to guarantee it supports sensor calibration and data visualization features for accurate readings and clear display. Consider these factors:

- Compatibility with sensor types and communication protocols like I2C or SPI to ensure smooth data transfer.

- Adequate processing capabilities to handle real-time sensor data and facilitate sensor calibration routines.

- Built-in or compatible interfaces for connecting display modules, aiding in effective data visualization on-site.

Processing Power and Connectivity

Choosing a microcontroller with adequate processing power and reliable connectivity options guarantees your weather station can handle real-time data processing and seamless communication with sensors and peripherals. This guarantees accurate sensor calibration and efficient data analysis, which are vital for reliable weather measurements. Opt for a unit that supports multiple communication protocols like Wi-Fi, Bluetooth, or LoRa, enabling flexible data transmission in remote locations. Adequate processing capacity allows you to implement algorithms for sensor calibration, filtering noise, and interpreting data on the fly. Additionally, a robust connectivity setup reduces downtime and data loss, making your weather station more resilient during field operations. Selecting the right microcontroller balances performance with power efficiency, ensuring your device remains portable without sacrificing functionality. Understanding regional resources and tools can help you choose the most suitable hardware for your specific environment.

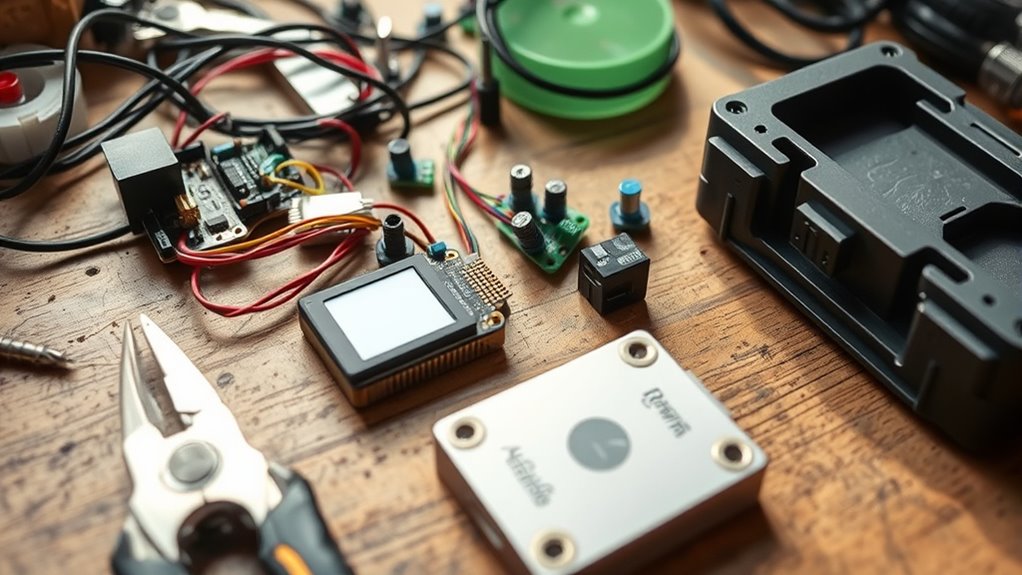

Gathering Necessary Materials and Tools

To build a reliable portable weather station, you’ll need to gather all essential materials and tools before starting. Proper sensor calibration guarantees accurate readings, so include calibration tools specific to your sensors. You’ll also want a sturdy enclosure to protect your components and ensure enclosure durability during field operations. Incorporating sensor tuning techniques can further improve the accuracy and reliability of your measurements.

Here are the key items to gather:

- Sensors (temperature, humidity, barometric pressure) with calibration kits

- A weatherproof enclosure made from durable materials

- A microcontroller or data logger with necessary wiring and power supply

Having these items ready allows you to focus on assembly and testing without delays, ensuring your station performs reliably in demanding field conditions.

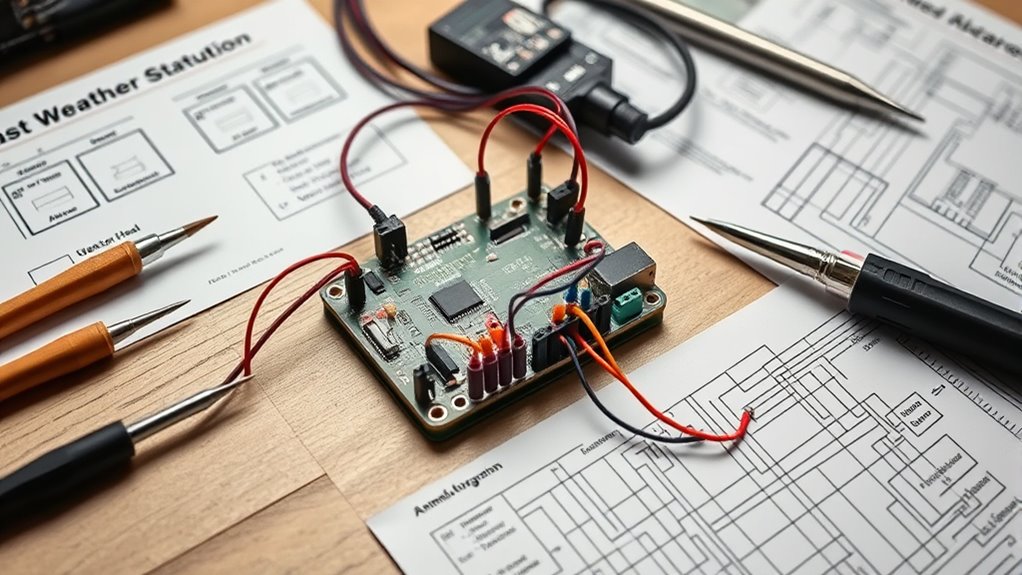

Designing the Circuit Layout and Wiring Diagram

Before assembling your weather station, it is crucial to plan the circuit layout and wiring diagram carefully. Start by deciding sensor placement to ensure accurate data collection and minimize interference. Place temperature and humidity sensors in well-ventilated, shielded areas, and position anemometers where wind flow isn’t obstructed. When designing the wiring diagram, prioritize wiring safety by using insulated wires, secure connections, and proper grounding. Keep wiring organized to prevent tangles and accidental disconnections. Use color-coded wires for easy troubleshooting and note the connections clearly. Plan the circuit layout to minimize wire length and reduce potential noise. A clear, well-organized diagram will streamline assembly and maintenance, guaranteeing your weather station functions reliably in the field. Additionally, understanding digital literacy programs can help ensure that users are capable of troubleshooting and maintaining the system effectively.

Assembling the Hardware Components

Assembling the hardware components is the crucial next step to bring your weather station to life. Start by carefully connecting sensors to your microcontroller, guaranteeing proper sensor calibration for accurate readings. Next, select enclosure materials that protect your components from environmental elements while maintaining portability. Secure all parts firmly within the enclosure, avoiding loose wires that could cause malfunctions. Make sure to double-check connections against your wiring diagram to prevent errors. Finally, test the assembled hardware briefly to confirm everything functions correctly. Proper assembly ensures durability and reliable data collection in field conditions. Taking the time to calibrate sensors and choose suitable enclosure materials now will save you troubleshooting later, setting a solid foundation for successful weather data gathering.

Programming the Microcontroller for Data Collection

When programming your microcontroller, you’ll focus on accurate sensor data acquisition and efficient data storage methods. You also need to implement power management strategies to guarantee your station runs reliably in the field. Mastering these points will help you create a robust and portable weather station. Incorporating filter maintenance strategies into your design ensures long-term performance and reliability of your sensors in the field.

Sensor Data Acquisition

Programming the microcontroller for data collection is a critical step in building your portable weather station, as it guarantees accurate and timely sensor readings. To verify reliable data, focus on sensor calibration to correct measurement inaccuracies. Next, set up your code to regularly gather data from each sensor, maintaining a consistent sampling rate. Additionally, implementing high refresh rates in your data acquisition process ensures smooth and responsive real-time monitoring. Finally, implement data visualization techniques within your program to monitor real-time sensor outputs effectively. Here are key steps:

- Calibrate sensors to improve measurement accuracy.

- Write code to acquire data at regular intervals.

- Integrate data visualization for quick analysis.

This approach helps you maintain precise, real-world readings and simplifies troubleshooting during field operations. Proper programming ensures your weather station delivers dependable data, ready for further processing or storage.

Data Storage Methods

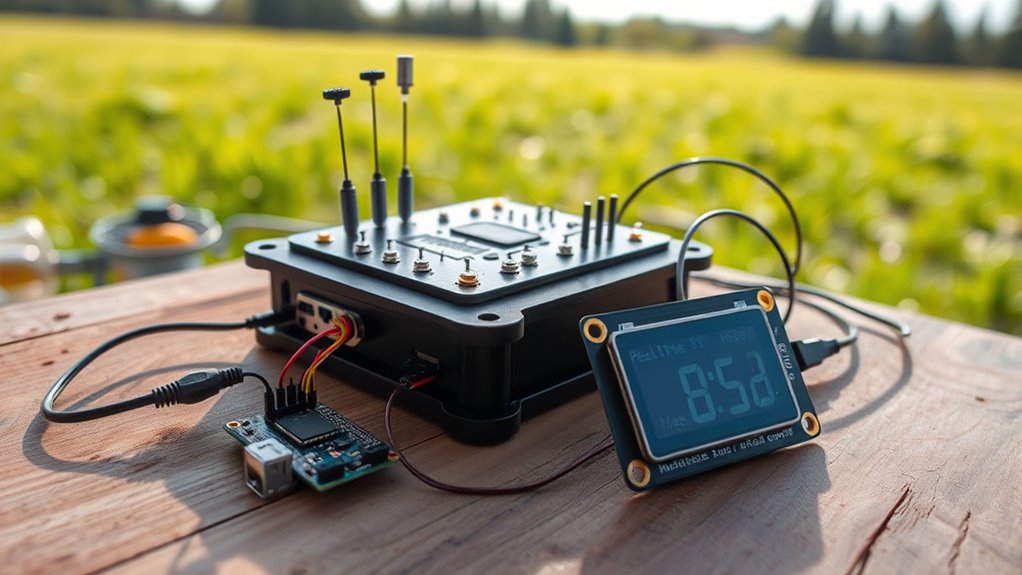

Choosing the right data storage method is essential for ensuring your weather station can reliably record and access sensor data during field operations. Cloud data storage offers real-time access and easy remote monitoring, making it ideal for continuous data collection. However, it requires a stable internet connection and sufficient bandwidth. Alternatively, SD card integration provides a straightforward, offline solution. You can program your microcontroller to save data directly to an SD card, ensuring data is stored locally even without internet. This method is simple to implement and great for rugged environments. Depending on your needs, you might combine both methods—storing data locally on an SD card while periodically uploading it to the cloud for backup and analysis. Choose based on your operational environment and data accessibility requirements. Additionally, considering sustainable practices in your data management can help minimize environmental impact and promote ethical technology use.

Power Management Strategies

Effective power management is essential to guarantee your microcontroller efficiently collects and stores weather data without draining the battery prematurely. To optimize power consumption, consider programming your microcontroller to enter sleep modes during inactivity and wake periodically for data collection. Incorporate solar panel integration to supplement power and reduce battery reliance. Focus on these strategies: 1. Use low-power modes and schedule data sampling at intervals to minimize energy use. 2. Implement sleep cycles between measurements, waking only when necessary. 3. Optimize your code and hardware to enhance power consumption, and ensure your solar panel effectively recharges the battery during field operations. Additionally, understanding AI Ethicist Jobs can help inform responsible design choices for autonomous systems involved in weather data collection.

Calibrating Sensors for Accurate Measurements

Calibrating sensors is a crucial step to guarantee your portable weather station provides accurate measurements in the field. Proper sensor calibration ensures measurement accuracy, which is essential for reliable weather data. Begin by referencing known standards or calibration sources for each sensor type. For example, compare your temperature sensor readings against a calibrated thermometer, or verify humidity sensors with a saturated salt solution. Regular calibration helps identify and correct sensor drift over time, maintaining data integrity. Keep detailed records of calibration procedures and results for future reference. Avoid assumptions that sensors stay accurate without calibration; environmental factors can affect performance. By dedicating time to calibration, you ensure your weather station delivers precise, trustworthy data during field operations.

Building a Portable and Durable Enclosure

Choosing the right materials guarantees your enclosure withstands harsh conditions, while effective weatherproofing keeps your sensors protected. You’ll want a design that balances strength with lightweight portability, so it’s easy to carry and set up in the field. Focusing on these points helps create a durable, reliable housing for your weather station.

Material Selection for Durability

Selecting the right materials is essential for ensuring your weather station’s enclosure can withstand rugged field conditions. Durable materials protect internal components, prevent material corrosion, and maintain sensor calibration over time. When choosing, consider these options:

- Polycarbonate or ABS plastics – impact-resistant, lightweight, and resistant to corrosion, ideal for protecting sensitive electronics.

- Stainless steel or aluminum – sturdy and corrosion-resistant, suitable for mounting hardware and structural frames.

- Coated metals or treated plastics – provide extra protection against environmental factors, extending the enclosure’s lifespan.

Weatherproofing Techniques Implemented

To guarantee your weather station remains operational in harsh field conditions, implementing effective weatherproofing techniques is essential. Start by using rainproof cables to prevent water ingress along wiring. Ensure all cable entries are tightly sealed and routed away from potential water flow. Apply high-quality sealant around joints, connectors, and entry points to create a waterproof barrier. Sealant application should be thorough, covering gaps and cracks where moisture could penetrate. Additionally, choose enclosure materials with weather-resistant properties, such as UV-stabilized plastics or coated metals. Regularly inspect seals and cables for damage or wear, reapplying sealant as needed. These measures help maintain the station’s integrity, safeguarding sensitive electronics from rain, humidity, and other environmental factors during field operations.

Structural Design for Portability

Designing a portable weather station requires creating an enclosure that balances durability with lightweight construction. A modular frame makes assembly and repairs easier, allowing you to customize the setup for different field conditions. Focus on a compact design that minimizes bulk without sacrificing protection for sensitive components. To achieve this, consider these key points:

- Use lightweight, impact-resistant materials like ABS or polycarbonate for the enclosure.

- Incorporate a modular frame system that allows quick disassembly and component replacement.

- Ensure the design maintains a low profile, reducing wind resistance and making transportation simpler.

These steps ensure your weather station is both durable and portable, ready for challenging field operations while remaining easy to carry and set up.

Testing and Troubleshooting Your Weather Station

Before deploying your weather station in the field, it’s essential to thoroughly test its components to guarantee accurate readings. Start by checking sensor calibration to ensure each sensor provides precise measurements. Calibrate temperature, humidity, and pressure sensors according to manufacturer instructions, then verify their outputs with known reference standards. If readings seem off, follow troubleshooting procedures—inspect wiring, tighten connections, and test power sources. Use a multimeter to identify faults or loose contacts. Confirm that sensors respond correctly in controlled conditions before field deployment. Document calibration results and troubleshooting steps for future reference. Proper testing now prevents inaccurate data collection later, saving you time and effort in the field. Consistent calibration and systematic troubleshooting are key to reliable weather station performance.

Implementing Data Logging and Wireless Communication

Once your weather station components are calibrated and troubleshooting is complete, setting up data logging and wireless communication guarantees your data is recorded accurately and transmitted seamlessly. First, choose a reliable wireless protocol—like Wi-Fi or LoRa—that suits your field environment. Next, configure your microcontroller to log sensor calibration data and environmental measurements into an onboard SD card or cloud storage, making certain of continuous data capture. Finally, test your wireless connection by transmitting sample data to verify stability and range. This setup allows you to monitor real-time weather conditions remotely and ensures your data remains intact, even in remote locations. Properly implementing these steps makes your portable weather station both efficient and dependable for field operations.

Frequently Asked Questions

How Long Can the Weather Station Operate on a Single Power Source?

Your weather station’s operation time depends on its power consumption and battery life. If it uses low power components, it can run longer on a single charge—potentially several days or weeks. Higher power devices shorten this period. To maximize uptime, choose energy-efficient parts and use larger or rechargeable batteries. Regularly monitor battery levels to guarantee consistent data collection, especially in field conditions where access to power sources may be limited.

What Are Common Issues Faced During Calibration and How to Resolve Them?

Calibration is like tuning a musical instrument; if you miss a beat, everything’s out of sync. Common issues include sensor misalignment and drift over time. To fix these, regularly check and adjust sensor alignment, and establish a consistent calibration frequency to keep data accurate. Neglecting these steps can lead to unreliable readings, so stay vigilant and perform calibration routines often to maintain precision.

Can the Weather Station Function in Extreme Weather Conditions?

You wonder if your weather station can handle extreme weather conditions. With proper design, it can achieve some level of extreme weather resilience, but sensor durability is vital. Using rugged materials and protective enclosures helps prevent damage from heavy rain, wind, or snow. Regular maintenance and calibration also guarantee consistent performance. While no device is entirely indestructible, these measures greatly enhance your station’s ability to function reliably in harsh environments.

How Do I Ensure Data Accuracy Over Long-Term Deployments?

So, you want your weather data to be perfect forever, huh? Well, start with regular sensor calibration to keep measurements honest. Don’t forget data validation—double-check your readings against reliable sources. This way, you catch errors early and maintain accuracy over long-term deployments. Remember, in the world of weather stations, complacency is your enemy; stay vigilant, calibrate often, and validate diligently to guarantee your data remains trustworthy.

What Safety Precautions Should Be Taken During Assembly and Operation?

During assembly and operation, you should prioritize electrical safety by guaranteeing all connections are properly insulated and grounded. Always wear protective gear like gloves and safety glasses to prevent injuries. Keep your workspace dry and clear of clutter to minimize risks. Follow manufacturer instructions carefully, and disconnect power when making adjustments. These precautions help protect you from electrical hazards and ensure safe, effective operation of your weather station.

Conclusion

Building your portable weather station is like crafting a reliable compass for field operations—you’ll gain precise, real-time data wherever you go. With careful sensor selection, solid assembly, and thorough calibration, you’ll create a tool that’s both durable and accurate. Keep testing and refining, and your station will serve as a steadfast guide through the unpredictable outdoors. Just like a compass points true north, your station will point you toward better weather insights.