Sustainer motors and self-launchers serve different roles in propulsion systems. Sustainers run efficiently over time, helping you maintain altitude or extend flight duration, while self-launchers provide quick, high-thrust energy for an immediate lift-off. If you need longer endurance and smoother operation, a sustainer suits your needs. For rapid ascent and decisive launches, a self-launcher is better. To understand which fits your mission best, explore their specific advantages and use cases further.

Key Takeaways

- Sustainer motors provide efficient, continuous thrust for long-duration flight, while self-launchers deliver high initial thrust for quick lift-off.

- Sustainers consume less energy per thrust unit, enabling extended operational periods; self-launchers require high power for rapid ascent.

- Sustainer systems are simpler to install and maintain, whereas self-launchers involve complex mounting and wiring for high-thrust deployment.

- Use sustainers for stability, altitude control, and extended flights; choose self-launchers for rapid, reliable lift-off in constrained environments.

- Selecting between them depends on mission goals, with sustainers optimizing efficiency and self-launchers prioritizing quick, high-power launches.

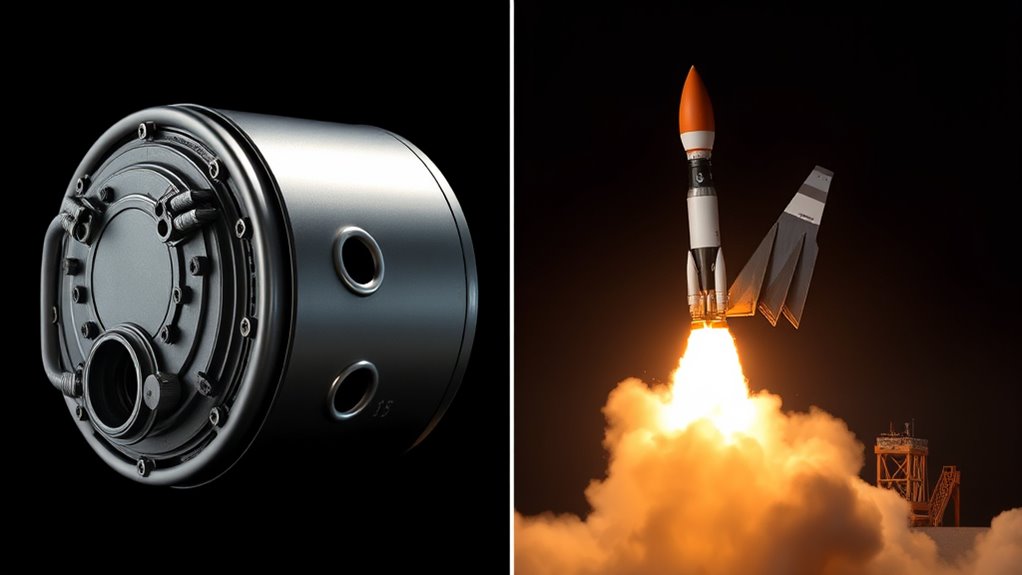

When choosing between sustainer motors and self-launchers, understanding their core differences is essential for making an informed decision. These two propulsion systems serve distinct roles in aerospace applications, and knowing how they compare can help you select the right option for your project. One of the primary factors to consider is battery efficiency. Sustainer motors are designed to operate efficiently over extended durations, making them ideal for maintaining altitude and providing continuous thrust once the initial boost is achieved. They typically consume less energy per unit of thrust during sustained flight, which translates into longer mission durations and better overall efficiency. In contrast, self-launchers focus on delivering a rapid, powerful burst of energy to lift the vehicle off the ground. They often require higher current loads during launch, which can lead to increased battery drain. This means that, unless your design incorporates high-capacity or specialized batteries, self-launchers may be less efficient for prolonged operations but excel at quick, decisive lifts.

Sustainer motors excel in efficiency and extended operation, while self-launchers prioritize rapid, high-thrust lift-offs.

Installation complexity is another critical aspect that differs profoundly between these systems. Sustainer motors tend to have a straightforward installation process because they are designed for integration into the vehicle’s existing propulsion architecture. Their modular design often allows for easier maintenance and replacement, reducing downtime and technical challenges. Conversely, self-launchers can be more complex to install. They often involve specialized mounting mechanisms, additional safety features, and intricate wiring to handle the high power loads required during launch. This complexity can extend the setup time and may demand more technical expertise, especially when adapting to different vehicle configurations. If ease of installation and maintenance are priorities for your operation, sustainer motors generally offer a more accessible solution.

Furthermore, you should consider the operational context. Sustainer motors are suited for missions that require sustained, stable flight, such as long-distance gliding or altitude maintenance. Self-launchers are better for scenarios where quick, reliable lift-off is necessary, like launching from constrained environments or when a rapid ascent is essential. Your choice might also depend on the available space, weight constraints, and safety protocols. Sustainers tend to be lighter and more predictable, while self-launchers often involve higher risks due to the intense power delivery involved during the launch phase.

Ultimately, your decision hinges on balancing efficiency, installation demands, and the specific requirements of your mission. If maximizing battery life and simplifying installation are top priorities, sustainer motors are likely your best choice. If rapid launch capability and high thrust are more critical, then self-launchers may fit your needs better. Understanding these core differences enables you to optimize your system for performance, safety, and efficiency, aligning with your operational goals.

Frequently Asked Questions

Which System Is More Cost-Effective Long-Term?

You find that self-launchers are more cost-effective long-term because their initial investment often costs less, and maintenance expenses tend to be lower. When doing your cost analysis, consider the budget considerations, including operational savings and reduced dependence on external launch services. Over time, self-launchers can save you money, especially if you plan frequent launches, making them a smarter choice financially.

Can Both Systems Be Combined in One Aircraft?

You can absolutely combine sustainer motors and self-launchers in one aircraft, creating a hybrid system that’s like having the best of both worlds. This integration boosts operational flexibility, allowing you to adapt to different mission needs seamlessly. Hybrid integration enables efficient launches and sustained flight, making your aircraft more versatile and responsive. It’s a game-changer that maximizes performance and reduces limitations, giving you unparalleled control and capability.

What Are the Maintenance Requirements for Each?

You need to perform regular inspections and tune-ups for sustainer motors and self-launchers to guarantee ideal fuel efficiency and reduce environmental impact. Sustainer motors typically require maintenance of their turbines, filters, and cooling systems, while self-launchers need checks on their launch mechanisms and structural integrity. Consistent maintenance helps prevent emissions and improves overall performance, making your aircraft more eco-friendly and cost-effective over time.

How Do Weight and Size Compare?

You’ll find that sustainer motors are typically larger and heavier, which can impact aerodynamic efficiency and overall aircraft design. Self-launchers tend to be more compact and lightweight, enhancing maneuverability and fuel economy. When considering propulsion technology, these size and weight differences influence how each option fits your mission needs. Smaller, lighter self-launchers improve aerodynamic efficiency, while larger sustainer motors may require more structural support but offer greater power.

Are There Specific Certification Challenges?

Certification hurdles can feel like climbing a steep mountain, but they’re essential for safety and compliance. You’ll face regulatory hurdles that demand rigorous testing, documentation, and approval processes, especially with self-launchers due to their complex systems. Sustainer motors might encounter fewer challenges, yet both require thorough certification to meet industry standards. Staying proactive and understanding these hurdles guarantees smooth certification, helping your project soar without unexpected turbulence.

Conclusion

Understanding the differences between sustainer motors and self-launchers is like choosing between a reliable bicycle and a powerful motorcycle—you need the right tool for your journey. Sustainer motors keep your project moving smoothly once airborne, while self-launchers handle the entire lift-off process themselves. By knowing their unique strengths and use cases, you can select the perfect option for your mission. Ultimately, choosing the right motor system ensures your launch is successful and aligns with your specific goals.