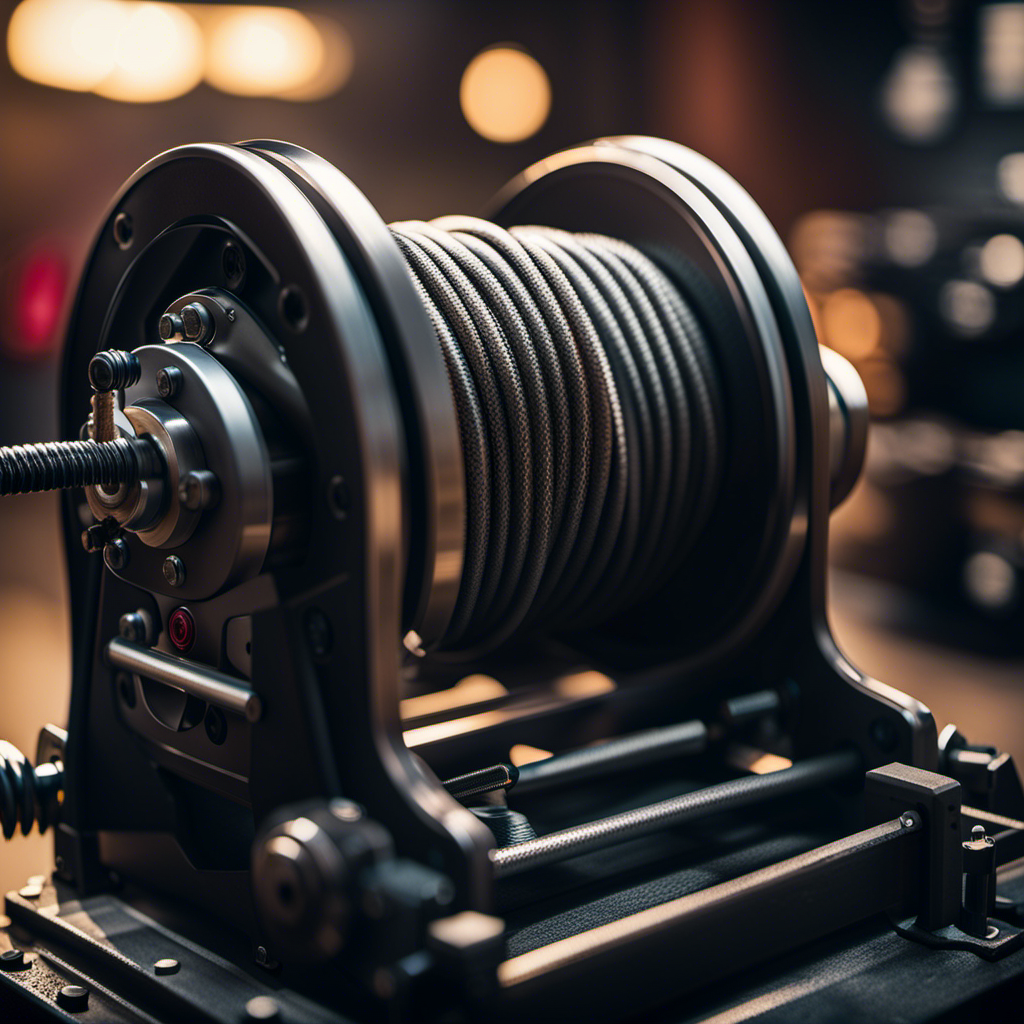

I have always been interested in the RPM of a winch. How does it affect its performance? What factors contribute to this? And most importantly, how can I adjust it to enhance the winch’s efficiency?

In this article, we’ll delve into the technical details of winch RPM, exploring its role in different applications and troubleshooting common issues. Whether you’re a professional or a DIY enthusiast, understanding the RPM of your winch is crucial for achieving optimal performance.

Let’s dive in and unravel the mysteries of winch RPM together.

Key Takeaways

- Operating a winch within the recommended RPM range ensures safety and performance.

- Exceeding the recommended RPM can lead to component failure and increase fire hazards.

- High RPM compromises load stability and can cause accidents.

- Regularly inspecting the winch for signs of wear or damage and maintaining proper cooling system function can prevent overheating and ensure optimal RPM performance.

Understanding the Basics of RPM

RPM stands for ‘revolutions per minute’ and is a commonly used measurement to determine the speed at which a winch operates. When it comes to winch speed, RPM plays a crucial role.

To calculate the RPM of a winch, you need to know the diameter of the winch drum and the line speed. The line speed is the rate at which the winch cable is being pulled in or let out. By dividing the line speed by the circumference of the winch drum (which is calculated by multiplying the diameter by π), you can determine the number of revolutions the winch drum makes in one minute.

For example, suppose the line speed is 10 feet per minute and the winch drum’s diameter is 2 feet. To calculate the RPM, you would divide the line speed (10 feet per minute) by the circumference of the winch drum (2 feet x π ≈ 6.28 feet). This would give you an RPM of approximately 1.59.

Understanding the RPM of a winch is essential in evaluating its performance. The RPM directly affects the speed at which the winch can pull a load. Higher RPMs result in faster line speeds, allowing for quicker and more efficient operations. On the other hand, lower RPMs may provide more pulling power but at the cost of slower line speeds.

Therefore, it is crucial to consider the role of RPM in winch performance to choose the appropriate winch for your specific needs.

The Role of RPM in Winch Performance

To optimize the performance of your winch, you’ll want to consider how the speed of rotation impacts its overall effectiveness. Understanding winch speed, RPM (rotations per minute), and winch pulling capacity is crucial for achieving the desired results in your winching operations.

RPM refers to the number of rotations a winch makes in a minute. It directly affects the pulling capacity of the winch, as a higher RPM generally results in a higher pulling capacity. This is because a winch with a higher RPM can generate more torque and power, allowing it to exert greater force on the load being pulled.

To better understand the relationship between RPM and winch pulling capacity, let’s take a look at the following table:

| RPM | Pulling Capacity (lbs) |

|---|---|

| 500 | 2,000 |

| 1,000 | 4,000 |

| 1,500 | 6,000 |

| 2,000 | 8,000 |

| 2,500 | 10,000 |

As you can see, as the RPM increases, the pulling capacity of the winch also increases. This information can help you choose the right winch for your specific needs, considering the load you’ll be pulling and the desired speed of operation.

Factors affecting winch RPM include the power source, gear ratio, and load resistance. These will be discussed in detail in the subsequent section.

Factors Affecting Winch RPM

When considering factors that affect the RPM of your winch, you’ll want to take into account the power source, gear ratio, and load resistance. These factors play a crucial role in determining the speed at which your winch operates.

The power source is a key factor in determining the RPM of your winch. If you have a high-powered motor, it will be able to generate more torque, resulting in higher RPM. On the other hand, a low-powered motor will produce lower RPM.

The gear ratio of your winch also affects its RPM. A higher gear ratio will provide more mechanical advantage, allowing the winch to rotate at a higher speed. Conversely, a lower gear ratio will reduce the RPM.

Load resistance is another important factor to consider. The more resistance your winch encounters, the slower the RPM will be. If you’re trying to increase the RPM of your winch, reducing the load resistance can help achieve that.

Finding the Ideal RPM for Your Winch

Finding the ideal RPM for your winch can greatly enhance its efficiency and overall performance. The right speed is crucial in ensuring that your winch operates optimally and safely. To calculate the ideal RPM for your winch, consider the following:

-

Determine the load capacity: Understanding the maximum load your winch can handle is essential in finding the right RPM. Higher load capacities may require lower RPMs to maintain control and prevent strain on the winch motor.

-

Consider the winch drum size: The diameter of the winch drum affects the required RPM. Smaller drum sizes require higher RPMs, while larger drum sizes can operate efficiently at lower RPMs.

Calculating the ideal RPM for your winch involves finding the balance between load capacity and drum size. It is essential to consult the manufacturer’s specifications and guidelines to ensure accurate calculations. Adjusting the RPM to match the specific requirements of your winch will optimize its performance and prolong its lifespan.

Transitioning into the importance of RPM in different winch applications, it is crucial to understand how RPM affects various winching tasks.

Importance of RPM in Different Winch Applications

Understanding how RPM affects different winching tasks is crucial for optimizing performance and ensuring safe operation. In industrial winches, the RPM, or revolutions per minute, plays a vital role in determining the winch’s effectiveness and durability. The importance of RPM in industrial winches lies in its impact on power and torque output.

Higher RPMs generally result in increased power and torque, allowing the winch to handle heavier loads more efficiently. However, it is essential to strike a balance as excessively high RPMs can put excessive strain on the winch components, leading to premature wear and tear. On the other hand, too low RPMs may not provide enough power to handle demanding tasks, compromising the winch’s performance.

Finding the optimal RPM for a specific winching application involves considering factors such as the weight of the load, the distance it needs to be moved, and the terrain conditions. By carefully selecting and maintaining the appropriate RPM, users can enhance the winch’s durability and ensure it performs reliably in various situations.

With the importance of RPM in mind, let’s now explore its impact on winch safety.

RPM and Winch Safety

In the previous subtopic, we discussed the importance of RPM in different winch applications. Now, let’s delve into the crucial aspect of RPM and winch safety.

When it comes to operating a winch, understanding the relationship between winch speed and RPM safety is essential.

The winch speed, measured in feet per minute (FPM), is directly related to the RPM of the winch motor. RPM, or revolutions per minute, refers to the number of complete rotations the winch motor makes in a minute. It is crucial to operate the winch within the recommended RPM range specified by the manufacturer for optimal safety and performance.

Exceeding the recommended RPM can lead to several safety hazards. Firstly, it can put excessive strain on the winch’s components, potentially causing them to fail. Secondly, high RPM can generate excessive heat, increasing the risk of overheating and fire hazards. Lastly, operating the winch at an unsafe RPM can compromise the load’s stability, leading to accidents or damage to the surrounding environment.

To ensure RPM safety, always refer to the winch’s manual for the recommended RPM range. Regularly inspect the winch for any signs of wear or damage that may affect its RPM performance. Additionally, proper maintenance, such as lubricating the winch’s moving parts, can help optimize its RPM and extend its lifespan.

Now, let’s move on to the subsequent section, where we will discuss common RPM-related issues and troubleshooting methods.

Common RPM-related Issues and Troubleshooting

One common issue related to RPM is overheating, which can be resolved by checking the winch’s cooling system. When the winch is operated at high RPMs for an extended period of time, the increased friction can generate excessive heat. This can lead to damage to the winch’s internal components and decrease its overall performance.

To troubleshoot this problem, it is essential to inspect the cooling system. Start by checking the winch’s fan to ensure it is functioning properly. Clean any dirt or debris that may have accumulated on the fan blades, as this can obstruct airflow and cause overheating. Additionally, inspect the winch’s coolant levels and make sure they are within the recommended range. If the coolant is low, it may be necessary to top it up or replace it altogether.

Regular maintenance of the cooling system can prevent overheating and extend the lifespan of your winch.

Upgrading your winch for higher RPM requires careful consideration and evaluation. It is essential to choose a winch that is specifically designed for high RPM applications. Additionally, upgrading the cooling system to handle the increased heat generated at higher RPMs is crucial.

Upgrading Your Winch for Higher RPM

When it comes to upgrading your winch for higher RPM, there are two key points to consider:

-

Gear ratio modification: This involves changing the ratio between the number of teeth on the input and output gears. By modifying the gear ratio, you can increase the speed at which the winch operates. This upgrade can greatly improve the performance of your winch, allowing you to complete tasks more efficiently.

-

Motor upgrade: Another option is to replace the existing motor with a more powerful one. A motor upgrade involves getting a motor that is capable of delivering higher RPMs. By upgrading the motor, you can increase the speed and power of your winch, making it more efficient and effective.

Both of these upgrades, gear ratio modification and motor upgrade, can significantly improve the performance of your winch. They allow you to operate at higher RPMs, making your winch more capable and efficient in completing tasks.

Gear Ratio Modification

To modify the gear ratio, you could try adjusting the pulley size on the winch. By analyzing the gear ratio, we can evaluate the performance of the winch and determine if a modification is necessary.

The gear ratio is a measure of how many times the winch drum rotates for each rotation of the motor. A higher gear ratio means the winch drum rotates more times per motor rotation, resulting in increased speed but reduced pulling power. On the other hand, a lower gear ratio provides more pulling power but decreases the speed.

Adjusting the pulley size can alter the gear ratio, allowing you to customize the winch’s performance to suit your specific needs. However, if you’re looking for a more significant improvement in RPM, you may consider upgrading the motor.

Motor Upgrade

If you want more power and speed, upgrading your motor is the way to go. When considering a motor upgrade for your winch, it is important to carefully examine the motor specifications and power requirements.

Look for a motor that can provide the necessary torque and horsepower to meet your specific needs. Consider the voltage and current requirements, as well as the motor’s efficiency and durability. A higher quality motor with better performance characteristics can greatly enhance the capabilities of your winch.

By upgrading your motor, you can increase the pulling force and speed of your winch, allowing you to tackle more challenging tasks with ease.

Now, let’s delve into the relationship between rpm and winch efficiency, and how it impacts the overall performance of your winch.

RPM and Winch Efficiency

You can increase the efficiency of your winch by maximizing its RPM. Understanding winch speed and how it relates to efficiency is crucial for optimal performance. Here are three key factors to consider:

-

Gear Ratio: The gear ratio determines the speed and torque of the winch. By selecting a gear ratio that allows for higher RPM, you can increase the speed at which the winch operates. However, it’s important to strike a balance between speed and torque, as too high of an RPM can result in reduced pulling power.

-

Motor Power: A more powerful motor can generate higher RPM, allowing the winch to operate at greater speeds. When choosing a winch, consider the motor’s horsepower and torque ratings to ensure it can handle the desired RPM without straining.

-

Load Capacity: The weight being pulled by the winch affects its RPM and efficiency. Heavier loads require more torque and lower RPM to maintain control and prevent damage. Understanding the load capacity of your winch and adjusting the RPM accordingly will help maximize its efficiency.

By considering these factors and optimizing the RPM of your winch, you can achieve improved performance and efficiency.

Transitioning into the subsequent section about ‘Conclusion: Optimizing Winch RPM for Improved Performance,’ it is clear that understanding and adjusting the RPM is crucial for getting the most out of your winch.

Conclusion: Optimizing Winch RPM for Improved Performance

By considering the factors discussed, it becomes evident that optimizing the RPM is crucial for achieving improved performance with your winch. Upgrading winch components and understanding the impact of winch size on RPM are key aspects to consider when aiming for better performance.

To illustrate the relationship between winch size and RPM, let’s take a look at the following table:

| Winch Size (inches) | RPM |

|---|---|

| 8 | 3500 |

| 10 | 3000 |

| 12 | 2500 |

| 14 | 2000 |

| 16 | 1500 |

As we can see from the table, as the winch size increases, the RPM decreases. This means that a larger winch will have a slower rotational speed compared to a smaller winch. It’s important to note that this decrease in RPM is due to the increased mechanical advantage provided by the larger winch.

To optimize the RPM for improved performance, consider upgrading your winch components. High-quality gears, bearings, and motors can help increase the RPM and ensure smooth operation. Additionally, choosing the right winch size for your specific needs is crucial. If you require higher pulling power, a larger winch with a lower RPM might be the best option.

Frequently Asked Questions

Can I manually adjust the RPM of my winch?

Yes, you can manually adjust the RPM of your winch. This allows you to control the speed of the winch, providing benefits such as precise positioning and increased safety. Techniques include adjusting the motor controls or changing the gear ratio.

How does the weight of the load affect the RPM of a winch?

The weight of the load directly affects the rpm of a winch. As the load increases, the winch’s power decreases, causing a decrease in rpm. This is due to the relationship between rpm, torque, and power.

Are there any safety precautions to consider when operating a winch at high RPM?

When operating a winch at high rpm, it is important to follow safety precautions. These include wearing proper protective gear, ensuring the load is properly secured, and staying within the recommended rpm range to prevent accidents and equipment damage.

Can using a winch at a higher RPM damage the winch or the load?

Using a winch at higher RPM can potentially damage both the winch and the load. The increased speed puts more strain on the winch’s components, reducing its durability and potentially causing mechanical failures.

What are some common signs of RPM-related issues with a winch?

Common signs of rpm-related issues with a winch include abnormal noise, overheating, and reduced pulling power. Common causes may include motor problems or mechanical issues. Troubleshooting steps involve checking the motor, inspecting the gears, and ensuring proper lubrication.

Conclusion

In conclusion, it’s imperative to optimize the RPM of your winch to enhance its overall performance.

By understanding the basics and factors influencing RPM, you can ensure efficient operation in various winch applications.

Troubleshooting RPM-related issues and considering an upgrade for higher RPM can further enhance your winching experience.

Remember, finding the ideal RPM is crucial for maximizing winch efficiency. So, take the time to fine-tune this vital aspect of your winch and unlock its true potential.

With a heart that soars as high as the skies, Aria, affectionately known as “Skylark,” is the driving force behind Soaring Skyways. Her journey into the gliding world began as a young dreamer gazing up at the soaring birds, yearning to experience the weightlessness and freedom they embodied. With years of experience both in the cockpit and behind the scenes, Aria’s commitment to the gliding community is unwavering.